Rated voltage:220VAC

Rated flow:1.5m3/min

Outlet dew:lower than -40°C

Rated pressure:0.4-2Mpa

Joint size:G1

Inlet air temperature: 5- 30°C

Product size:32.5*24*73cm

Weight:40kgs

Advantages of modular adsorption dryer:

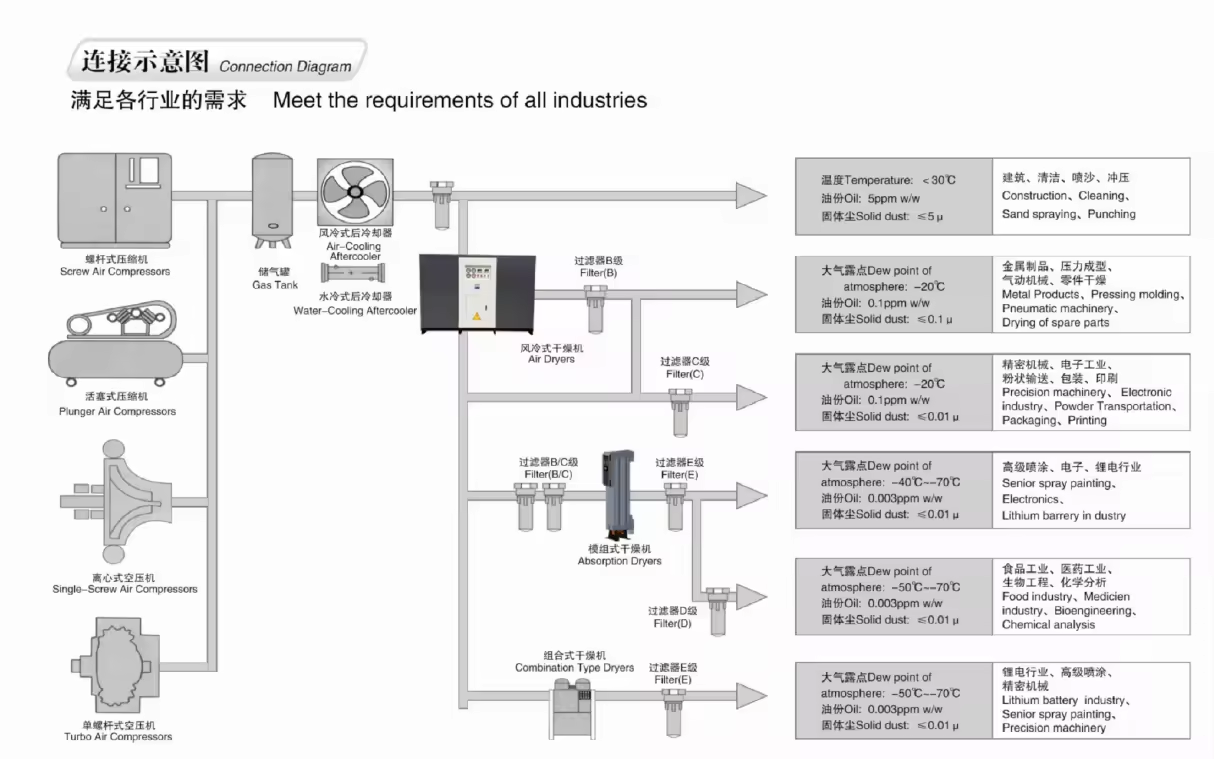

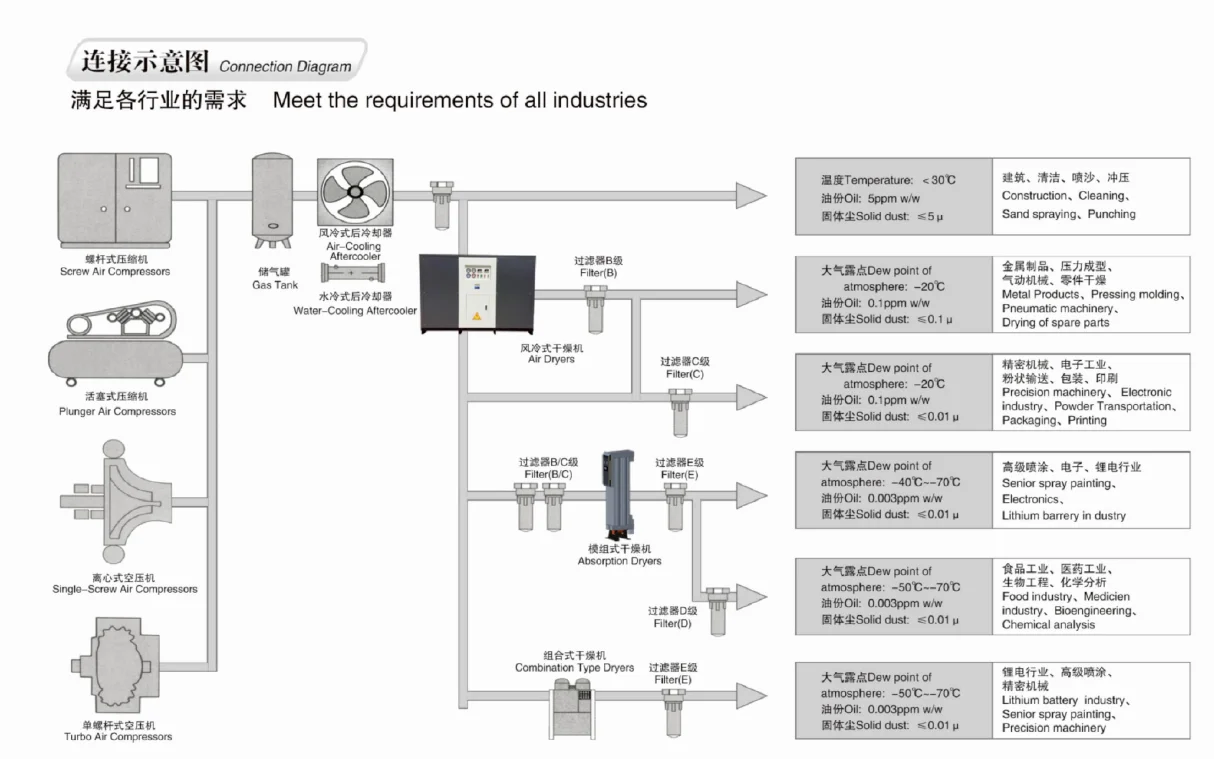

* The operating pressure is 0.4MPa-2.0MPa, which is widely used in laser cutting industry, powder storage and drying, advanced

spraying, medical, food industry, chemical industry

* Engineering, film, electronics, precision instruments, aerospace industry.

* Energy saving: Air consumption ≤ 5 is the biggest energy-saving effect, reducing the operating cost of compressed air by 30% - 60%.

* High efficiency: The regeneration gas can flow through the adsorption pipeline without dead space, so the regeneration gas can be

used more fully.

* Stable: The multi pipe modular design of the adsorption chamber and the unique design of the cylinder block make the body structure

very compact and reasonable, breaking through the traditional double tower external.The shape of the whole equipment is beautiful and

generous.

* Clean: It is made of aerospace aluminum alloy and never rusts.

* Low pressure drop; The inlet and outlet buffer chambers are designed to make the gas flow through the inlet and outlet buffer

chambers to form convection through the adsorption chamber, thereby reducing the pressure drop.

* Long service life: the service life can reach 30 years after oxidation and rust prevention treatment.

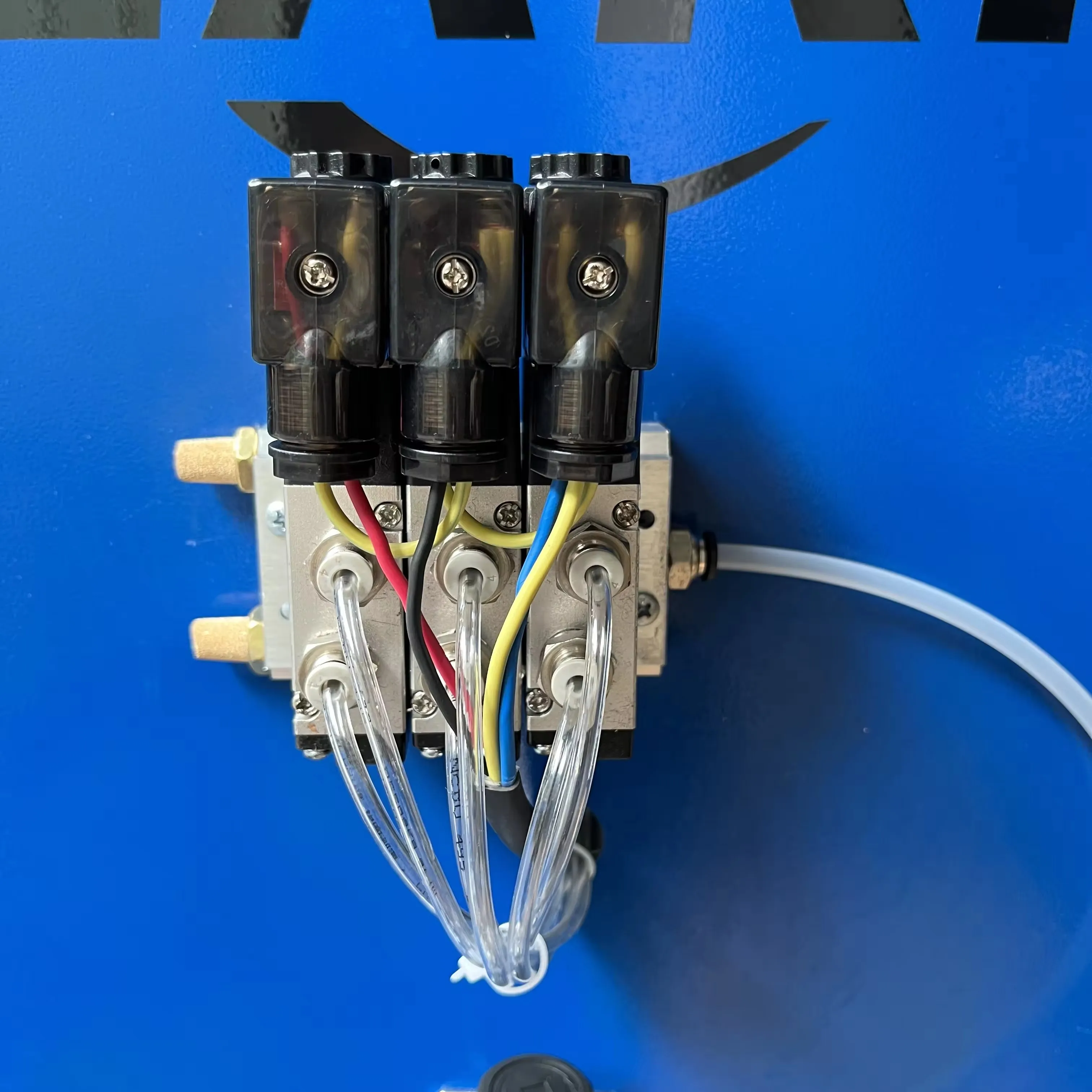

*Easy maintenance: To replace the adsorbent, just use an Allen wrench to remove four screws from the top cover, and the muffler can

be removed and replaced with a slight twist.

*The unique sound attenuation and emission design can fully discharge the water adsorbed on the adsorbent surface, reducing the

consumption of regeneration gas.

*It does not belong to the special inspection scope of pressure vessels. The volume of a single adsorption cylinder is less than 25L, so it is unnecessary to recheck the pressure vessels every year, which saves a lot of time and cost.