Wet Blasting Machine

Automatic Wet Blasting Machine for high value industrial components

The Automatic Wet Blasting Machine is specially designed for high value industrial component surface processing, it is suitable for high value industrial components pre-coating treatment, post-coating treatment and passivation treatment.

The equipment is consisted of automatic feeding unit, blasting unit, rinsing unit, slurry concentration detecting unit, automatic sand replenishing unit, ultrasonic rinsing unit, clean ultrasonic rinsing unit, drying unit, automatic discharging unit, sand supplying unit, mixing unit, fine sand filtering unit.

Types of automatic wet abrasive sandblasting machine

1.single chamber wet blasting machine: used only for surface treatment or passivation treatment

2. Dual chamber wet blasting machine: It is used for both surface treatment and passivation treatment simultaneous, improving the flexibility of equipment to a great degree

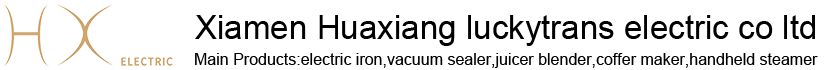

Feeding mechanism

Servo motor and synchronous belt are used instead of ordinary motor to control the moving position, realizing closed-loop control of position, speed and torque. The motion accuracy is +/-0.01mm, possessing stronger stability. It can bear 20 pallets.

YZ traveling mechanism

n motion accuracy: +/-0.01mm

n y-axis motion range: 0-550mm

n z-axis motion range: 0-200mm

n use servo motor in place of steeping motor to control moving position

Blasting chamber

The blasting chamber has a separate blasting area with 2 slurry pumps and 2 sets of blast guns for each area. The configuration of 16 blast guns allows the pallets to be treated in different blasting process formulations. The blasting gun crown is in the form of imported spray gun to ensure the quality of sandblasting. Its characteristics are constant pressure of sandblasting slurry, uniform flow and large flow of sandblasting outlet.

Separating drum

In order to ensure the stability of sandblasting, separating coarse and fine sand can be used to filter out fine sand for the stability of abrasive particle size in slurry.

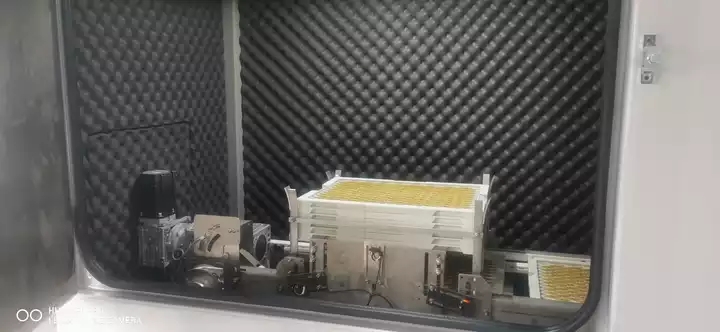

Mass flow meter

In order to ensure the stability of sandblasting products, our equipment can automatically detect the particle size of slurry regularly and in real time. When the granularity of slurry is low, it can automatically feed media. When the slurry concentration level exceeds the preset control range, the monitoring device will forbid the equipment to start blasting.

Automatic and manual measurement range: 5%-15%

Rinsing unit

The high-pressurized water produced by the generating device washes against the metal surface, which also cuts and grinds it. This unit makes dirt, grease, rust, oxide scale and other smear peeled off instantaneously on the metal surface to have metal surface shown metallic luster, reaching desired state.

Ultrasonic casting and washing mechanism

Under the effect of ultrasonic wave radiation, micro bubbles of the liquid in the sump are kept vibrating. It will break down the adhesion between smear and the surface of the workpieces, which will cause dirt layer fatigue and to be stripped off. The vibration of gas bubbles will scrub the surface of the workpieces. Water heating and slurry conveyor allows the washing process cleaner and quicker.

Pre-coating surface treatment

By adopting wet blasting technology, excessive cobalt can be removed from the surface of the edge, which may have reverse effect on the cohesion of the surface coating. Slight wet blasting technology enables the cohesion of surface coating to reach HF1 (the highest level of cohesion) while not generating static electricity or absorbing dust.

Post-coating surface treatment

During the process of treating double-color inserts, our equipment gives a excellent performance with stable consistency and homogeneity.

Inserts passivation

Increasing hone edge radius can greatly reduce the contact length and heat accumulation of inserts and swarf so that reduce inserts wearing. By adjusting blasting pressure and blasting angle, wet blasting can meet the required hone edge radius of inserts. Reaching passivation maximum of 70um, this machine can completely replace conventional methods. The working life of inserts will increase by 30%-70%, the utilization rate of inserts will be improved, and customers’ cost will be decreased.

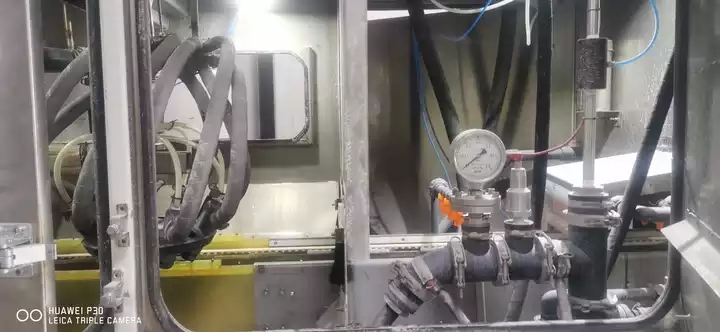

Control system

This intelligent system adopts PC-based control elements produced by BECKHOFF(Germany), and has strong control function. Modularized programming methods allow our control system to be more stable and reliable and with incomparable control efficiency.

Control network

The control network of this system uses EtherCat real time control bus, the most advanced technology on the market. It has 100Mbps transmission rate and connecting is quite easy. Realizing network control greatly reduces wiring control, makes the circuit in the worksite tidy and clean, changes the past dense circuit in the worksite, and simplifies faulty circuit troubleshooting, greatly improving equipment maintenance efficiency. Driving technology applying network improves the position accuracy and saves time for servo control, and anti-interference ability is also strengthened to a great extent.

Interactive interface

This system uses human-machine interfaces based on Windows system. This interface boasts great interactivity and easy system operation, allowing operators to handle the machine under simple training. The system integrates SQL (Structured Query Language) standard database and stores information of machine operation. The power of generating blasting formula can tackle workpiece production changes during the process.

Remote maintenance

With internet, our system can conduct remote maintenance easily. We can help customers cope with problems in the worksite within 24 hours. Customers’ equipment value will be enhanced infinitely.

System performance Parameters

No. | ITEM | PARAMETER |

1 | blasting type | water&sand |

2 | sandblasting concentration range | 5-30% |

3 | online testing concentration and automatic feeding | yes |

4 | online testing slurry PH value and automatic adjustment | yes |

5 |

grit dislodgement and filtration | yes |

6 | cleaning methods | Ultrasonic wave+rotating+clean water rinsing |

7 | drying methods | high pressure air quick blow(without water stain) |

8 | feeding pallet quantity |

20 pallets |

9 | Surface treatment efficiency | >25,000pcs/day |

10 | insert treatment | pre-coating and post-coating treatment &passivation |

11 | gas source treatment and filtration | yes(optional) |

12 | compress air pressure | >0.6Mpa |

13 | Slurry pressure range |

0-0.4Mpa |